<Thermo Riko’s Solution>

#1 High Speed, High Temperature

MAX. heating rate 300℃/sec.

Reaching 1,500℃ at Maximum.

Conventional resistance heating systems raise temperature slowly, requiring a significant amount of time to achieve a high temperature. This limits the number of tests feasible within a day, extending the product development cycle as well.

MAX. heating rate 300℃/sec.

Reaching 1,500℃ at Maximum.

It’s hard to raise temperature of a moving sample with a direct heating system, which may cause damages to the surface of such sample. It could also destroy a sensor touching the surrounding area.

Enable to heat the sample without physically contacting it.

Conventional heating systems raise temperature of a sample itself, and its peripheral temperature as well. There is a risk of damage to a sensor touching the surrounding area.

Heating only the samples

without surroundings.

Conventional systems, such as electrical resistance heaters, may emit gas pollutive to a sample.

Eliminating the risk of air pollution.

Conventional systems only raise temperature from specific angles. This limits the available heating methods.

Infrared beams irradiate the sample

from any angle 360°

With conventional systems, a heater must be placed inside a vacuum environment. This could contaminate a sample with the emitted gas.

Enable to Heat the samples

in a vacuum atmosphere.

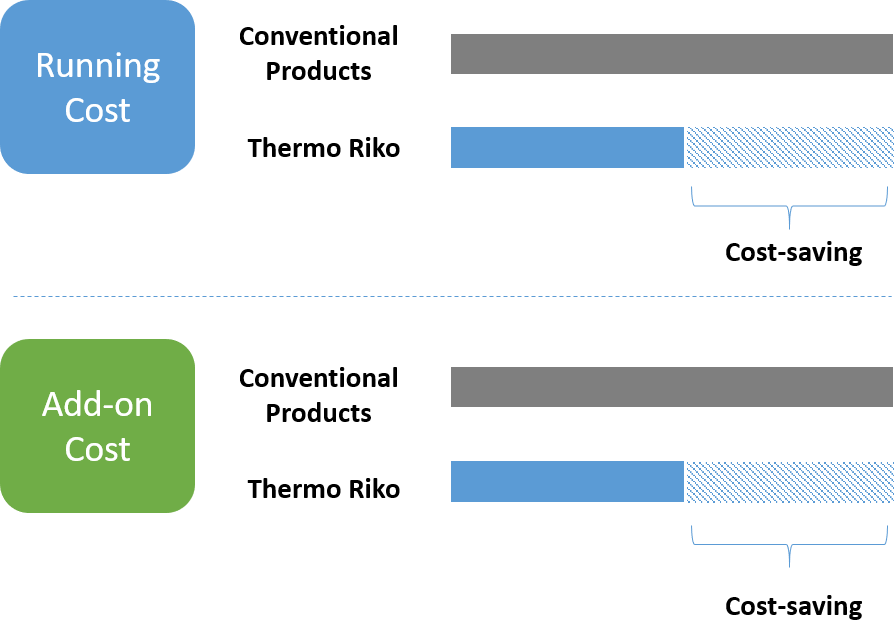

Adding a new heater to an existing system requires a large-scale modification, which may involve a significant cost. Such modification may be simply impossible due to space and/or structural issues.

Can be attached to your equipment. All you need is only 1 port.

Conventional systems usually require an electrical power of 10kW. As described above, it also requires a long time to raise temperature of a sample, extending the overall development time and causing more cost. Besides, it usually involves a significant cost to add a new system.

Only 2kw required for operation.

Less investment cost compared to Conventional ones.